Quality Benefits

Optifine grain refiner, in conjunction with Opticast technology, is achieving exceptional results in the routine production of many demanding and high-quality alloys in casthouses worldwide.

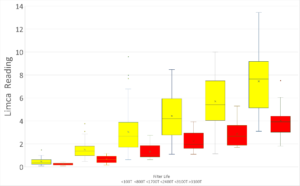

Improving melt quality by reducing the inclusions added due to lower addition of grain refiner during the manufacturing process improves downstream product quality for your customer. By reducing the addition rate, the amount of potentially harmful, inclusion related particles are reduced by the same amount. A study in a major casthouse using LiMCA has confirmed this.

Benefits to the casthouse

Using a consistent high efficiency grain refiner reduces the number of aborted casts, the costs associated with those aborts and the need to downgrade products, particularly after lengthy and costly post casting treatments.

A summary of quality improvements seen by Optifine customers:

| Slab Casting | Billet Casting |

|---|---|

| Reduced incidence of v cracks and slag patches on | Elimination of razor streaks on high gloss automotive extrusions |

| Reduction in incidence of cracked slabs | Ability to extrude ultra-thin complex sections |

| Reduction in pin holes in thin sheet | Higher extrusion rates |

| Reduction of edge cracking on rolling | Longer Die Life |

| Faster casting speeds |

Further Benefits

Reducing your grain refiner purchase volume, by adopting Optifine will have a positive effect on our environment by reducing the Carbon footprint of the manufacturing process of Aluminium.

In the casthouse there will also be a reduction in inventory which releases precious warehouse space. At the casting pit, the frequency of coil changes will be reduced thus improving the health and safety of the workers and in turn, there will be a reduction of both internal and external transportation costs.