What is it? A pioneering grain refiner testing system

Why Opticast? To establish efficiency of grain refiners

What are the benefits? Improved efficiency and cost savings on grain refiner

Opticast enables casthouses to determine the precise amount of grain refiner they need to achieve optimum refinement, no more guesswork. Opticast, which can be operated by casthouse personnel, has now been introduced in over 20 casthouses.

Opticast enables casthouses to determine the precise amount of grain refiner they need to achieve optimum refinement, no more guesswork. Opticast, which can be operated by casthouse personnel, has now been introduced in over 20 casthouses.

Casthouses can establish the consistency of the efficiency of the grain refiner they use to reduce surface blemishes, cracking and defects using Opticast at their own plants or at our technology test centre at BCAST at Brunel University London.

Traditionally, this has been a guessing game for casthouses and struggling to maintain the same grain size in the melt every time has had wide-ranging repercussions, including scrapped charges, product downgrades and higher processing costs.

As the only testing system in the industry, it is helping casthouses worldwide meet demand for higher internal and surface quality in slabs and billets from ever more discerning manufacturers.

The Opticast unit has recently been upgraded and redeveloped and this means that the  unit is now fully automated and all the functions such as polishing/anodising time, electrolyte flow rate etc. are controlled using an HDMI screen. Opticast requires the use of electrolytes for electrolytic polishing and anodising the aluminium samples and these are contained in external containers for ease of changing and storage. By pressing the start button on the home screen the turntable indexes to a home position before moving to the polishing, rinsing and anodising positions. When the cycle is completed the turntable moves back to the home position. The safety interlock on the lid prevents the unit from operating if it is not fully located.

unit is now fully automated and all the functions such as polishing/anodising time, electrolyte flow rate etc. are controlled using an HDMI screen. Opticast requires the use of electrolytes for electrolytic polishing and anodising the aluminium samples and these are contained in external containers for ease of changing and storage. By pressing the start button on the home screen the turntable indexes to a home position before moving to the polishing, rinsing and anodising positions. When the cycle is completed the turntable moves back to the home position. The safety interlock on the lid prevents the unit from operating if it is not fully located.

OPTIMISING GRAIN REFINEMENT

The Opticast System is a unique technology and methodology for the in-line control and optimisation of grain refinement.

In conjunction with Optifine it has been successfully adopted into routine production at many aluminium plants worldwide where it is reducing costs and increasing quality.

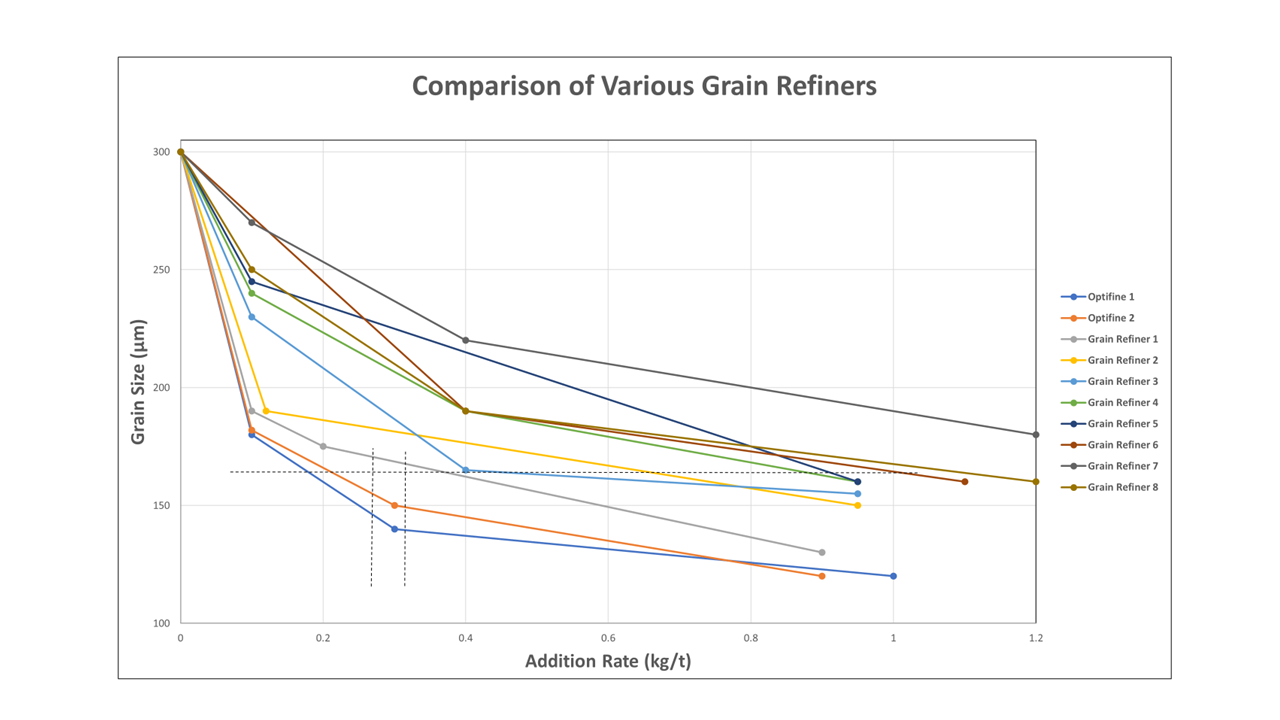

In order to adopt Optifine into the casting process calibration of the current casting practise is an important step to determine how a specific alloy responds to addition of fresh nuclei via the grain refining rod. This involves using the Opticast system to measure the grain size and then establishing the equations for grain refinement curves of Optifine and commercial TiBAl grain refiners, generating data such as in the graph shown for an AA 1050 alloy.

Grain refinement in an AA 1050 alloy illustrating the much lower amount of Optifine than the amount of commercial grain refiners needed to obtain a grain size of around 150 µm.

To view / download our Opticast Product Information Sheet you need to Register or Login first.

Please note: we manually review registrations so please allow us 1 business day to approve your account, thank you.

To view / download our Optifine Product Information Sheet you need to Register or Login first.

Please note: we manually review registrations so please allow us 1 business day to approve your account, thank you.